Heat-strengthened glass (TVG)

Naturally also part of the plentiful product range from NOWAK GLAS: heat-strengthened glass (TVG)!

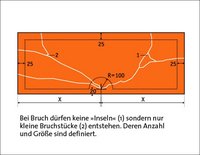

The production process for heat-strengthened glass as per EN 1863 is very similar to that for toughened safety glass. Here too the panes are heated in the thermal strengthening process up to a temperature of more than 600°C and then blown with convective cold air. The crucial difference is that the cooling phase is much more restrained. This results in a glass with thermal and mechanical properties between float glass and ESG.

We always recommend TVG when the resilience and thermal shock resistance of normal float glass is not sufficient, but ESG with its fracture pattern (crumbly structure) would not offer the necessary residual load capacity in the case of breakage.

It is only when TVG undergoes further processing to become laminated safety glass (VSG) that it acquires safety properties. This results in a safety glass that offers an ideal combination of constructive and, above all, active and passive safety properties.

The combination of augmented flexural strength, thermal shock resistance and residual load capacity offers ideal prerequisites for use as partitioning, overhead glazing, point-fixed glazing and structural glass elements, such as stairs.

NOWAK GLAS holds the national approval No. Z-70.4-125 from the DIBt (Centre of Competence in Civil Engineering) for heat-strengthened glass. This covers both monolithic TVG and also VSG made of 2 x TVG for use in linear-supported and point-fixed glazing solutions. Special approval in individual cases is therefore no longer necessary. The advantage for our customers: there is no longer any need for costly, time-consuming bending, breakage and component tests!